Exterior

Exterior

StyLight® – a new material highlight

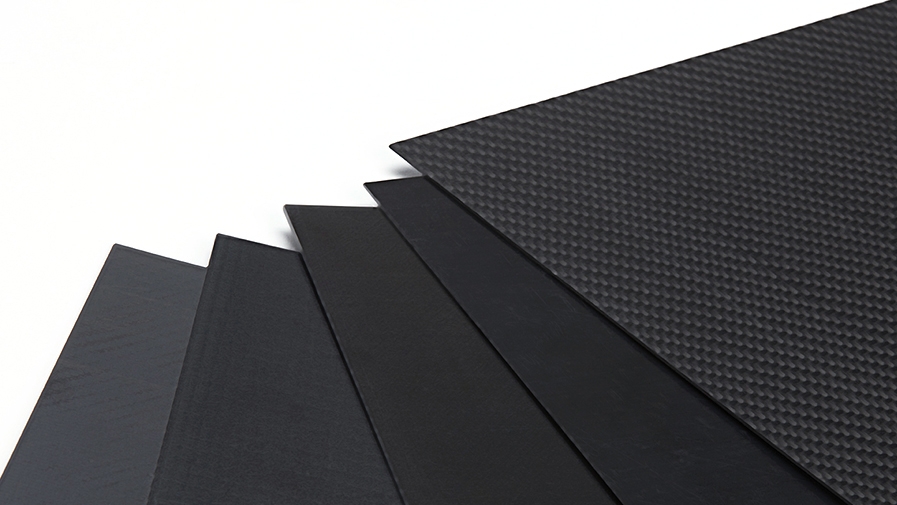

INEOS Styrolution offers StyLight as semi-finished sheets. The product consists of a composite material based on a modified SAN or modified PP matrix and diverse fibre textile (carbon fabric, glass fabric or hybrid) for semi-structural aesthetic applications or purely structural applications.

INEOS Styrolution’s StyLight portfolio has been growing significantly since its launch in 2016. With the success of this new material, INEOS Styrolution decided in 2019 to develop a dedicated manufacturing site to produce StyLight.

With the material coming of age, the interest of the automotive industry in thermoplastic composite is constantly growing and it is considered for an increasing number of applications by leading OEMs globally.

Partnerships with companies such as Roctool, ARRK Shapers’, Rehau and INTOPS have led to the full validation of StyLight according to the automotive specification of leading car manufacturers.

ARRK Shapers’ developed an inner trim made of StyLight Aesthetic S C245-1 painted with a clear coat. The material has been developed for applications in which especially visual appearance and surface quality are important. Carbon-fibre thermoplastic back-moulded offers a lightweight solution when compared with epoxy based carbon composites.

Hyundai has developed an aesthetic exterior carbon application that is coated in the mould with a liquid resin system based on polyurea, made by Panadur, resulting in a deep 3D effect and protecting the material against scratches and UV. The moulding process is done by INTOPS.

Roctool designed an engine hood prototype made of StyLight Aesthetic S C245-1. Producing large aesthetic carbon parts with a short cycle time and without post treatment steps were a challenge. The combination of the Roctool inductive mould heating technology with StyLight allows to produce parts with a high surface quality direct from the mould. The use of StyLight in combination with the Roctool technology can simplify the production of automotive interiors and exteriors and mass production.

Finally, StyLight Structural S has been explored by Rehau, a leading supplier of polymer based solutions, to develop a co-extruded profile together with Luran S 797S. The combination resulted in a thin rigid and fatigue-stable profile with excellent weather and UV resistance. Adhesion is provided due to the chemical compatibility between both materials.